From the installation Movimenti della Memoria by Fabrizio Plessi. Photo: Einar Aslaksen.

The Wood Pulp Mill - «Living Factory»

A visit to the premises of Kistefos' oldest pulp mill gives insight into both the work process at the factory and what life was like at Kistefoss. We try to give the public a feeling of going back in time to when the forest was our most important natural resource and timber arrived at the pulp mill by means of the log conveyor from the river - and came out of the pulp mill attic as readily processed wood pulp.

Living Factory is a project where old machinery and industrial fixtures in the wood pulp mill have been revived, which breathes new life into the closed-down factory. Several machines can be started by our visitors.

In 2017, Kistefos started a project in the pulp mill meant to captivate the museum’s youngest visitors - and hopefully create an interest in Kistefos’ history. All the elements included in the project involve active play for young children - in combination with learning about what was taking place in the wood pulp mill when it was operational.

The pulp mill attic in the wood pulp mill is an exhibition arena with several zones communicating varied topics connected to A/S Kistefos Træsliberi. A part of the design of the exhibition zones is the use of digitalized and interactive solutions meant to captivate old and young visitors alike.

From the installation Movimenti della Memoria by Fabrizio Plessi. Photo: Einar Aslaksen.

Related reading:

-

From the installation Movimenti della memoria by Fabrizio Plessi. Photo: Einar Aslaksen.

Movimenti della memoria

The Italian artist Fabrizio Plessi visited Kistefos in 2001. The visit resulted in the installation Movimenti della memoria - which translates to ”The movement of memory”. Inspired by the feeling of a…

Read more

-

The Horse by Kristin Günther. Photo: Einar Aslaksen.

The Horse

The video artist Kristin Günther has created an interactive and dramatic installation based on Baroque ceiling paintings. While subjects in ceiling paintings traditionally address the viewer, we are h…

Read more

-

Homage to Leo the Lion

On a quiet day in the wood pulp mill, you can already hear Heske’s art film at the entrance. As you move down the floors of the building, towards the old turbines, the roar of the film will give you c…

Read more

-

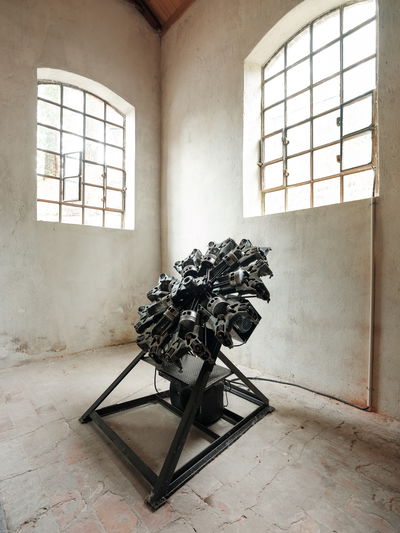

Sternmotor: Hochamt av Thomas Bayrle. Photo: Einar Aslaksen.

Sternmotor: Hochamt

Sternmotor: Hochamt is primarily an aircraft engine, a symbol of humanity’s continuing progress within the industrial and the material. However, the airplane, both before and after 9/11, also gives as…

Read more